|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| volume 2, number 3/4 : winter 2004/2005 |

[Download free Acrobat Reader] |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Contents: the tech transfer process: researcher profile: spin-in: joint-research partnerships: teamwork and awards: events: Tech Transfer Metrics — July 1 – December 31, 2004 |

From the Center Director:

When President Bush outlined the new Vision for Space Exploration, I think all of us at Goddard—and around the nation—were struck by the bold scientific and mission goals. Could they be achieved in such a short time frame? What about the funding? But as with President Kennedy’s plans to reach the moon 40 years ago, great achievements often are spurred on by high expectations. A key aspect of the Vision is partnerships. The document specifically states that “NASA plans to work with other government agencies and the private sector.” By bringing together the great minds at NASA with those in industry, at universities, and within other federal labs, we can greatly accelerate the research and development (R&D) process for Space Exploration. Forming successful partnerships also is cost-efficient for NASA. Beyond the cost savings associated with completing R&D projects faster, bringing appropriate technologies into NASA can save money. In many cases (albeit not all), it is cheaper to buy something than to make it. And that’s why the infusion of technology from outside sources—also known as spin-in—is essential. Technology transfer has always been a NASA goal. From my experience as Program Scientist for the Hubble Space Telescope, I know how spin-out of NASA technology can impact human lives on Earth. As most of you know, a key Hubble technology has been applied to breast cancer diagnosis, providing a nonsurgical method for tissue biopsy. Spin-out still will happen, but we need spin-in to develop many cutting-edge technologies. As you pursue your research for Space Exploration, look for an opportunity to work with outside organizations. If they have something to bring to the table, contact Goddard’s Innovative Partnerships Program (IPP) Office. IPP can help forge the partnerships that will take us to the moon, Mars, and beyond. editorial I believe we researchers have drifted away from approaching technology transfer as originally intended. When NASA was first established, one of its primary purposes was to transfer space technology to benefit all Americans. We researchers have interpreted this to mean that we publish our NASA research results, and a grateful public simply sticks them into some industrial application like plugging in a light bulb. But space R&D does not simply plug in that way. The inventor must carefully listen to industry and make adjustments to the technology so it fits the application. It is extra work, but we must do it anyway. The public rightly expects it of us, and it is our duty to deliver. Also, we must fully capitalize on the money and time invested in developing the technology to start with. I believe our management needs to rethink this also and to educate and persuade the R&D workforce to return to original intent. At present, we think technology transfer is the responsibility of IPP. I disagree. Technology Transfer is the responsibility of the inventor. IPP can help administer and guide tech transfer, but the actual transfer must be done by the inventor as part of his/her duties. For an inventor, transferring technology is a rewarding and satisfying two-way street. The inventor starts by listening to the customer describe the application and providing consulting services as the customer seeks to fit technology to application. Before long, the customer begins to contribute to practical development of the technology and to lowering its costs. With this new knowledge, the inventor sees ways to make the technology work better for NASA/space applications. Before long, a dialogue emerges and ideas move back and forth in a “win-win” scenario. It’s good for industry. It’s good for NASA. And it’s good for public relations. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

As we conclude our series examining the steps associated with spin-out of Goddard innovations to non-NASA applications, the Innovative Partnerships Program Office would like to thank the following inventors for their participation in the licensing of their technologies. These spin-out successes would not be possible without their dedication and cooperation. |

|

technology: Method of Coating a Substrate with a Rapidly Solidified Metal

licensed: January 2004

by: Titus Group (Spokane, Washington)

Goddard’s process for coating substrates with a rapidly solidifying metal uses a high-velocity spray that causes a metal powder and small peening particles to react during impact with a substrate, causing the metal powder to become solid and bond quickly.

Working with this technology gave Titus new insights into their own processes, enabling the company to make a significant leap forward with its products. As a result, the company merged to become Integrated Micrometallurgical Systems (IMS). The merger provided access to more equipment and new potential customers. For example, IMS’s new automotive components might be of interest to Formula 1 racecar manufacturers.

technology: High Rate Digital Demodulator (HRDD)

licensed: March 2004

by: Kongsberg Spacetec (Tromso, Norway)

Goddard’s HRDD technology is a receiver that enables incredibly fast—up to 600 million bits per second (Mbps)—digital demodulation and bit synchronization using dual-ASIC circuitry. This circuitry offers a more compact design and lower power requirements at a lower cost.

Kongsberg Spacetec licensed HRDD to build improved data-recovery systems for ground support of Earth observation satellites. Kongsberg will make HRDD receivers using chips purchased from a U.S. manufacturer, thus providing benefits to our economy. Kongsberg’s HRDD receivers then can be used to recover telemetry data, providing NASA—and Kongsberg’s customers—with integrated and reliable systems at a low cost.

technology: Systems and Methods for Determining Spacecraft Orientation

licensed: April 2004

by: a.i. solutions (Lanham, MD)

Goddard’s Multimission Attitude Determination System (ADS-MATLAB) is a unique software system for analyzing and processing spacecraft attitude sensor and actuator data. It provides a complete set of portable tools that can be applied to most spacecraft, and its highly adaptable architecture allows it to conform to specific mission configuration requirements.

Under its copyright-patent license agreement, a.i. solutions will provide ADS-MATLAB as a commercial product, integrating it into its premier mission-planning product, FreeFlyer. The company will make it user-friendly; develop full documentation; and provide customer support, maintenance, and updates.

technology: Capaciflector Techologies

licensed: May 2004

by: Nytec, Inc. (Seattle, Washington)

Goddard’s capaciflector is used to sense distance between objects. The technology is highly precise, rugged, and durable. It has performed flawlessly on several NASA missions in extreme environments. It also is useful in a wide range of industries, including automotive, industrial robotics, and security.

Nytec has a prototype license agreement for the capaciflector. Under this agreement, Nytec may make prototype capaciflectors for its customers’ applications, such as collision avoidance and “smart” valves, airbags, and other devices. If those customers find that the technology meets their needs, they will license it directly from Goddard.

“Nytec does the best capaciflector sensor work I have seen to date,” said inventor John Vranish (Code 544). “They achieved the highest sensitivity and stability yet and all in record time. Equally important, the sensor array input, output, and management is all digital, which shows exceptional software and digital expertise.”

technology: Micro Pulse Lidar (MPL)

licensed: October 2004

by: Sigma Space Corp. (Lanham, MD)

|

The MPL technology makes lidar practical for routine monitoring of atmospheric particles, such as dust, pollution, and clouds. Unlike previous, traditional lidar systems, MPL is eye-safe, small, simple, reliable, long-range and operates unattended. The technology is significantly enhancing atmospheric research.

Sigma Space Corp. is making MPL available for continuous, unattended monitoring of cloud and aerosol profiles in the atmosphere. Environmental companies and researchers can purchase their own MPL with standard specifications or have the device modified for their particular use. Sigma’s MPL systems are in use in many lidar stations within the U.S. and worldwide, such as in Taiwan and Antarctica.”

Sigma Space has a well-established record for high-quality engineering and products for space flight and other research applications,” said inventor James Spinhirne (Code 613). “Their version of MPL includes the latest design and advances from NASA to improve performance and reliability of instruments.”

technology: Apparatus and Method Using a Holographic Optical Element for Converting a Spectral Distribution to Image Points

licensed: December 2004

by: JMAR Technologies, Inc. (Carlsbad, California)

Known as the Holographic Circle-to-Point Converter, this technology resolves the circular fringe patterns of light generated by a Fabry-Perot interferometer into focused points. The technology overcomes the limitations of circular photomultiplier-type detectors, reducing the cost, complexity, and size of Doppler lidar systems.

Previously licensed for other applications, the technology is now going to be used in the JMAR Technologies product BioSentryTM. BioSentry is a real-time, online system for continuous monitoring of drinking water supplies for users such as water utilities, bottled water beverage processors, and homeland security. Goddard’s technology increases the available design options for the product. JMAR is currently testing and evaluating BioSentry beta units and assembling the marketing, production, system installation, and customer support teams needed for product launch later this year.

“It’s exciting to see the technology being used beyond its specific NASA application in a broader social application,” said inventor Matthew McGill (Code 613). “And all this started because I was willing to work with IPP and take the technology to trade shows.”

![]()

researcher profile:

John Vranish

|

Code 544 Education: Born: Brainerd, Minnesota |

What invention are you currently working to transfer?

Actually, IPP is currently working on a few technologies: a capaciflector, gear bearings, a three-dimensional sprag, and a conformal gripper. All of these devices can be used in a broad range of mechanical applications.

What has IPP done to introduce these inventions to new users?

In addition to filing for patents, they have helped me publish these technologies in NASA Tech Briefs and present them at conferences trying to find licensees. They also helped me publish articles in Smithsonian Air & Space Magazine, Popular Science, Popular Mechanics, Mechanical Engineering Magazine, Design News, R&D Magazine, and Aerospace America. These efforts have been quite successful, particularly with the prototype license arrangement.

What do you see as the future for your technologies?

The gear bearing technology is currently on track to be used on the F-35 Joint Strike Fighter and eventually might be used in defense, NASA, and commercial aerospace as well as automotive applications. The capaciflector’s “virtual feel” capability is critical to space robotics precision assembly. Industry also will likely take a lead in using the technology, probably in operator-to-computer interfaces and/or valve performance monitoring devices.

Any advice for your colleagues?

See editorial above.

Spin-In

Moving Forward with a New Spin-In Process

Regular readers of this newsletter will note that we have concluded our series of articles explaining the Office of Technology Transfer’s process for transferring Goddard innovations to outside users in industry and academia—that is, spin-out. The next issue of Goddard Tech Transfer News will begin a similar series, this one related to spin-in.

As most of you know, spin-in occurs when:

- Goddard brings in a technology or capability from an external organization that fulfills a NASA need

- Goddard and industry collaborate on mutually beneficial technology development

- A Goddard-developed technology, facility, or capability fulfills the needs of any other government agency or program (particularly those within NASA) (For more information on the value of spin-in, see Dr. Weiler’s article.)

IPP is building systematic processes for harvesting NASA needs. We then call upon our team of civil servants and -contractors who have the technical expertise needed to identify possible solutions to meet those needs. Those needs and possible solutions guide us as we search for potential partners, fostering relationships to create spin-in success.

We hope to expand our spin-in successes from 2004, securing partnerships worth more than $1 million in tangible and intangible benefits to NASA. We hope you will join us as we move toward this goal. Upcoming newsletter articles will provide more information about how you can participate.

On the Road to Spin-In Success

As outlined in the article above, spin-in involves the infusion of technology and expertise from outside sources to help achieve NASA’s goals. One means of enabling spin-in to happen is through joint-research partnerships.

Established as Space Act Agreements (SAAs), joint-research partnerships bring together the best minds in NASA and the private sector, universities, and/or other government labs. Five such partnerships were established during 2004. During the coming year, IPP plans to implement even more spin-in partnerships.

Beth Israel Deaconess Medical Center (BIDMC)

The award-winning Hilbert-Huang Transform (HHT) technology is being used to help detect patients with impaired blood flow regulation in the brain that may increase the risk for stroke. HHT is a novel signal processing method for analyzing natural processes. Such signals cannot be analyzed accurately with the traditional Fast Fourier Transform (FFT) method because they are nonlinear and nonstationary. HHT provides an analytical method for physiological, environmental, industrial, structural and many other signals.

HHT’s inventor Norden Huang (Code 614) has been working with researchers at BIDMC in analyzing data on blood pressure and blood flow in the brain. Research shows that a drop in blood flow in the brain during a sudden reduction of systemic pressure in response to standing up may indicate impairment of the flow-pressure regulation in the brain. HHT can be used to analyze the pressure-flow relationship in clinical settings.

“HHT is ideal for analyzing very short data—data with only a few cycles of oscillation,” explained Dr. Huang. “In that sense, the way BIDMC is using HHT is very similar to how NASA is using it.” In fact, the partnership with BIDMC resulted in improvements to HHT that are now benefiting NASA as it analyzes wing flutter tests at Dryden Flight Center.

Syracuse University

In July 2004, Goddard signed an agreement with Syracuse University to jointly produce and evaluate the performance of lithium niobate (LiNbO3) fiber optic sensors. The thin film of LiNbO3 acts as a highly sensitive photoelastic and electrooptic boundary layer that responds readily to external strain.

Researchers at Goddard and Syracuse plan to work together to make an optical fiber modulator in the form of a D-shaped fiber with metal electrodes on the flat surface. By combining Goddard’s expertise in fiber optic technology with Syracuse’s full electrooptic lab, researchers will prepare and manufacture the LiNbO3 optical fibers. These fibers then will be tested in Goddard’s photonics laboratory.

By pooling their resources, both Goddard and Syracuse can advance their understanding of this innovative technology and its potential applications while expediting the development and testing process. This should yield benefits for NASA and the commercial sector, as explained by Tracee Jamison (Code 562). “These sensors can be embedded into materials, such as the wings of spacecraft, for real-time structural monitoring. The fiber also is being considered for application in security fences.”

New Scale Technologies

New Scale Technologies of Victor, New York, and Goddard will conduct joint research involving New Scale’s SQUIGGLE™ motor and Goddard’s Cryogenic Research and Integration Test Facility.

New Scale’s tiny SQUIGGLE™ motor is an ultrasonic piezoelectric actuator that uses vibrations in a threaded bushing to directly rotate a mating screw. NASA’s cryogenic instruments require millimeters of stroke, nanometer precision, and several Newtons of force while generating negligible vibration and heating. New Scale’s SQUIGGLE motor might meet those needs.

Under the Space Act Agreement, NASA and New Scale will work together to test and improve the cryogenic SQUIGGLE motor at temperatures as low as 4 Kelvin. The team will work together to identify and demonstrate motor improvements and publish the test results.

The partnership between New Scale and NASA Goddard is a natural fit, explained Goddard’s Peter Shirron (Code 552). “Not only does NASA have extensive cryogenic testing capabilities and experience, but we also need cold-qualified actuators for future space telescope missions.”

Mentor Technologies, Inc./MXF

Based in Lanham, Maryland, Mentor Technologies and its incubator company Monochromatic X-ray Filter Technologies, Inc. (MXF) have entered an agreement with Goddard to use its facilities to make advancements in X-ray technology. These facilities include Goddard’s multilayer deposition system, surface profile analyzers, reflectometers, and a confocal laser scanning microscope.

MXF will use these facilities to fabricate, calibrate, and verify prototypes of a monochromatic parallel X-ray filter. This filter may improve the resolution of X-ray machines used in medicine. Improving the machines’ resolution will enable doctors to reduce the amount of radiation patients are exposed to during cancer screenings and other detection procedures. The filters also might be applicable to the X-ray systems used in security applications. Furthermore, the data Mentor obtains during its work might be able to be used by NASA to improve construction of X-ray telescopes.

AdvR, Inc.

|

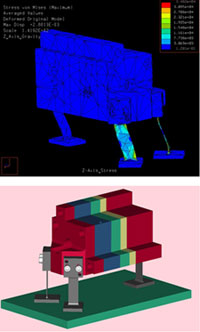

As part of its Laser Risk Reduction Program, Goddard has entered into an agreement with AdvR, an applied photonics company based in Bozeman, Montana. The program’s goal is to increase the stability, robustness, and lifetime of lasers used in long-term space missions, reducing mission risk. Injection seeding high-power lasers with a stable, single-frequency, low-power source can greatly improve the total laser system’s lifetime and improve the operational specifications (e.g., shot-to-shot stability, timing, frequency jitter). Such lasers exist commercially, but a flight-qualified version is very expensive, relatively inefficient, and massive for such a low-power device. Low-cost, efficient seed lasers are essential. AdvR develops and provides such seed lasers and other photonics technologies to its clients.

Working cooperatively, Goddard researchers and AdvR personnel are working to build a flight-qualified semiconductor seed laser. Beginning with an AdvR unit, Goddard is performing improvements to the package design using finite element analysis and other research to enable the laser’s mechanical components to withstand flight conditions. Then AdvR will assemble the improved components and test the optical power, electrical and optical efficiency, beam and spectral profile, wavelength, and frequency stability output. After laboratory specifications are met and verified, the laser will be go through a standard flight qualification procedure, including vibration and thermal vacuum testing.

“If this project is successful,” said Goddard’s Barry Coyle (Code 690), “NASA will be able to obtain commercially available flight-qualified semiconductor seed lasers for about one-tenth the cost and less than one-twenty-fifth the volume, weight, and electrical budget of the present alternative.”

Several projects utilizing this technology are already underway, including seeded fiber amplifiers and high-precision imaging and surface mapping. Its original use as a single-frequency source for high-power, solid-state lasers is still being pursued for more and larger laser systems destined for field, aircraft, or space use.

Teamwork Brings Ground-Breaking Technology into Use

|

|

The successful transfer of the award-winning Hilbert Huang Transform (HHT) technology is an excellent example of how collaboration yields great benefits.

In 2001, Semion Kizhner (Code 564) attended a colloquium where Norden Huang (Code 614) was presenting his HHT technology and its applications. Mr. Kizhner thought HHT could be more broadly used if the algorithms were integrated into a user-friendly, Windows-based system. Mr. Kizhner explored this idea with Tom Flatley (Code 586) and the Innovative Partnerships Program (IPP) Office.

Within 6 months, Mr. Kizhner and Mr. Flatley, along with Karin Blank (Code 586), submitted a proposal for funding from IPP. Now called the Technology Transfer Accelerated Partnerships (TTAP) program, TTAP funds R&D efforts that will help bring promising technologies to the marketplace quickly. The team was awarded funding and began system design and programming, led by Mr. Kizhner.

In the year it took to develop the first release of the software, IPP staff promoted HHT to potential users. Interest grew and grew. By the time the HHT Data Processing System (HHT-DPS) was available, IPP had a long list of people who were interested in evaluating the software. For those users outside the government, IPP provided 60-day demo versions of the software; government users had unlimited access to the software. Interest was further built when the development team presented a paper at the 2004 IEEE Aerospace Conference.

“Working with the IPP was great,” said Mr. Flatley. “They handle all of the software release, all of the paperwork, and all of the legal matters. It works out great and allows us to concentrate on our technical work.” For instance, David Petrick (Code 564) is examining the use of a field-programmable gate array (FPGA) to accelerate the data processing.

Due to the extensive interest—as of Jan. 31, 2005, more than 400 individuals have registered their interest in evaluating the technology—IPP needed an easy way to process the many requests for the HHT-DPS. A Web site was devised and an online system created that harnessed the power of the Internet to facilitate request processing.

Now the team is working with the intelligence community, a wireless communications company, medical researchers, and others to help make HHT-DPS meet their needs. “The benefit to us is that we get to do a lot of interesting things that we wouldn’t normally get to do. It opens a lot of unique opportunities for collaboration,” said Mr. Flatley.

“We all really like feeling like we’re contributing to something good,” summarized Mr. Flatley. “We feel good about making Norden’s technology useful to everybody.”

Submit Your NTRs to Qualify for NASA Awards

The second half of 2004 saw the bestowing of seven Space Act Awards to 16 Goddard researchers. These awards recognize significant scientific and technical contributions. In addition to the recognition by their peers, the researchers receive cash awards of up to $100,000.

- Holographic Circle-to-Point Converter by Matthew McGill (Code 613), Vibart Scott (Code 694), and Marzouk Marzouk (Sigma Research and Engineering)

- SHARM: Software Solving the Monochromatic Radiation Transfer Problem in Planetary Atmosphere Using Spherical Harmonic Methods by Alexei Lyapustin (University of Maryland–Baltimore County [UMBC])

- Earth Observing System Clearinghouse (ECHO) by Robin Pfister (Code 586), Michael Burnett (Global Sciences and Technology [GST]), Keith Wichmann (GST), Richard Newcomb (Blueprint Technologies), and Maitreyee Pasad (GST)

- Hierarchical Segmentation Software by James Tilton (Code 606)

- AutoCHEM by David Lary (UMBC )

- Micro Pulse Lidar by James Spinhirne (Code 613)

- Code-It by Thomas Winkert (Code 561), Edward Hicks (Code 564), David Petrick (Code 564), and David Fisher (QSS Group)

The Innovative Partnerships Program Office prepares the applications for these awards. In order to be eligible for a Space Act Award, the invention must have been reported to NASA via a new technology report (NTR), which can be completed on paper (NF-1679) or online (http://invention.nasa.gov/).

Events

IPP’s 2nd Venture Capital Project Workshop a Success

|

As reported in the Fall 2004 issue of Goddard Tech Transfer News, IPP is hosting a series of workshops designed to foster development of high impact collaborations as well as help build inventor interest in technology transfer partnerships. The second of these workshops was held December 9, 2004.

|

The 25 attendees heard a presentation from John Preston, who is CEO of Atomic Ordered Materials Corp. and an advisor to three venture capital firms. Having founded, directed, and invested in many technology companies, Mr. Preston discussed success factors for technology transfer and investment. Also presenting was John Fini of the Emerging Technology Center (ETC), who discussed technology readiness. In addition, a panel of Goddard research fund managers discussed the impact tech transfer can have on internal funding. And case study exercises used throughout the workshop reiterated the concepts presented.

Evaluations indicated that everyone found the workshop valuable, with 40% saying they found it extremely valuable. And nearly all indicated they would attend the next workshop, which will be held in April.

For more information about the third Venture Capital Project Workshop, which will focus on encouraging external partnerships, contact IPP (6-5810).

recent events

| event | technologies | outcome |

| SMART Tech Trends 2004 | Capaciflector-based technologies Thin-film parylene-C real-time sensor Cartesian and optical encoders Gear bearings |

|

| NASA Tech Briefs Nanotechnology Conference 2004 |

Carbon Nanotube Growth Process |

|

| Department of Commerce: Americans with Disabilities |

Compliant Cable Mechanisms Secure Ambulation Module (SAM) |

|

| 2004 Emerging Technologies Conference | Spin-in |

|

| NASA Goddard Tech Transfer Innovation Workshop Series |

Spin-in |

|

| NASA URETIs Partnering Workshop 2004 | Spin-in |

|

| Sensors Government Expo and Conference |

Spin-in: Dan Powell (Code 542) chaired panel on applications for carbon nanotubes |

|

| Solar Sail Technology and Applications Conference |

Spin-in |

|

![]()

Tech Transfer Metrics

July 1 to December 31, 2004

New technologies reported: 74

New technologies were reported by the following civil servants, contractors, and universities:

Civil Servants

|

Contractors: Ad Santec Universities: Brown University |

|

Issued Patents: 5Innovators receive a $500 to $1,000 award for an issued patent. (All links open new browser windows.)

Patent Applications Filed: 3

|

||

|

Provision Patents Filed: 6

|

||

We want to do all we can to make it easy and rewarding for you to participate in the Technology Transfer Program. But we need your help. Send us your ideas for program improvements or News articles via e-mail.

![]()

You can report new project technologies by submitting the online form on eNTRe.

![]()

A publication of

Innovative Partnerships Program Office

Mailstop 504

Building 22, Room 290

(301) 286-5810

techtransfer@gsfc.nasa.gov

![]()

+ Freedom of Information Act + The President's Management Agenda + Privacy Policy and Important Notices + Freedom to Manage |

Webmaster: Adil Anis NASA Official: Nona Cheeks Last Updated: June 25, 2012 + Contact NASA |

||